Product Knowledge

200T/H Ballast Crushing Production Line

author:dahua2 time:2023-12-18

Ballast stone is a gravel used to road or railway subgrade, mainly used for railway bed.The ballast stone supports rail sleepers in a railway transportation system, that is a

common track bed structure. The project will lay a layer of gravel on the subgrade before laying the rails, then compact it, finally lay the sleepers and rails. Using ballast

stone can make it easier to drain and adjust the position of rails. At the same time, because the ballast stone distributes the weight of train and rails on the roadbed, it can

reduce the vibration and noise caused by the train passing, so that it will increase the passengers' riding comfort.

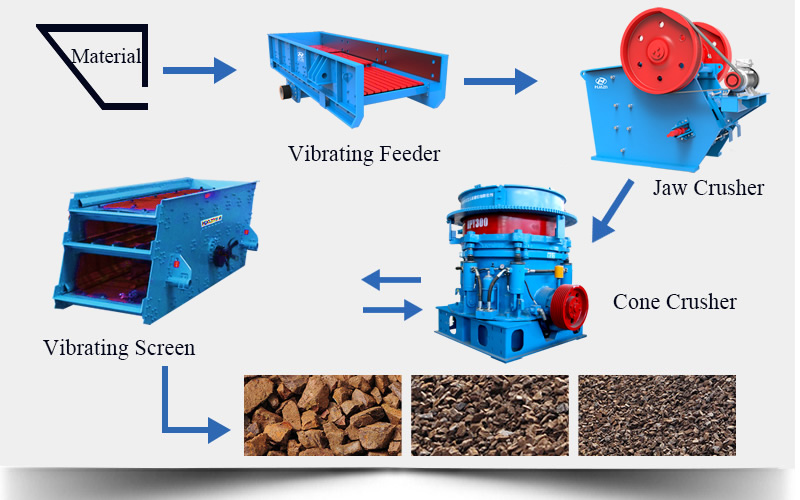

The main crushing equipment for ballast stone includes vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating feeder, vibrating screen, etc.; The main processing flow is as follows: Big ballast stone in silo is fed to jaw crusher evenly by vibrating feeder, then coarse crushing. The coarsely crushed material is conveyed to cone crusher by the belt conveyor. The material is sieved with a circular vibrating screen after crushing. The larger particle materials will be returned to the cone crusher and crushed again. Qualified materials are transported to the impact crusher through the finished product belt conveyor for reshaping. The reshaped products are transported to the product stacking area.

Ballast Stone Crushing Line Flow Chart

Material-Vibrating Feeder-Jaw Crusher-Cone Crusher-Vibrating Screen

Customer Site Of Ballast Crushing Line

200T Per Hour Ballast Stone Crushing Site in China

Discharging Size: 0-10-20-40-70mm

Usage of Final Product: Road, Railway

Main Equipments: Jaw Crusher, Cone Crusher, Impact Crusher, Vibrating Screen, Feeder, Belt Conveyor and Other Equipments

Other matters needing attention

1. Choose a stone crushing line manufacturer with rich configuration experience

The production process of stone crushing line needs to be developed by manufacturers with rich equipment configuration experience, because the production process configuration must consider many factors, such as material characteristics, topography, production capacity, angle and length of belt conveyor, etc. If there is no years of stone processing line configuration experience, in the later production process, there will be a series of problems such as the failure of the crushing equipment capacity, the insufficient conveying capacity, and the blockage of the feed.

2. On-the-spot investigation of relevant sand and gravel aggregate production lines

Any manufacturer with many years of experience in the configuration of stone crushing lines must have established production lines. When selecting the production equipment of the stone yard, it is recommended to visit other production lines built by the manufacturer, especially the production lines with similar production capacity and materials. On the one hand, you can have a reference function for the equipment of your own choice, on the other hand, it is also the quality inspection of the production line configured by the crushing equipment manufacturer that you will choose.

Previous Article:No Information

Next Article: How to start stone crusher plant business