Fault and Troubleshooting Method of Jaw Crusher (5)

author:dahua1 time:2018-12-04

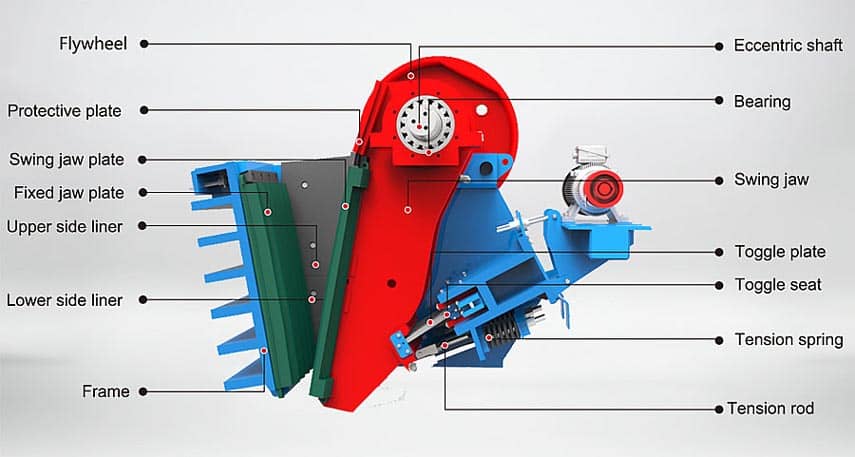

Fault phenomenon 1: The flywheel wheel swings axially to the left and right.

The reason:

1) The flywheel wheel hole, flat key or shaft wears and loosens;

2) The stone material is rolled into the inner side of the wheel, causing the flywheel wheel housing to crack;

3) Casting defects;

4) The flywheel wheel tension sleeve is loose.

Method of exclusion:

1) Wear the flat key, replace the flat key, or replace the eccentric shaft or the flywheel;

2) Add the flywheel guard and replace the eccentric shaft or the flywheel;

3) Replace the eccentric shaft or the sheave.

4) Re-tighten the tightening sleeve.

.jpg)

Fault phenomenon 2: The frame is crazing.

The reason:

1) Casting defects or welding quality defects;

2) Use of unqualified brackets and brackets, when the crusher is under strong impact, the brackets are not self-breaking, causing the frame to crack;

3) The fixed jaws are not fixed Long-term ups and downs, hitting the front frame of the rack;

4) The rigidity of the base of the base is poor or collapsed, the frame is beating;

5) The two bolts on the bearing cover are loose;

6) Fixed the movable jaws continue to be used after the tooth shape is worn;

7) The direction of the weight of the flywheel wheel is misaligned due to the eccentric shaft, the pin damage or the loosening of the sleeve.

Method of exclusion:

1) Remove the original crack defects, repair the repair, and replace the new frame if necessary;

2) Repair or replace the new frame, and replace the original bracket and bracket pad produced by the main machine factory.

3) Repair or replace the new machine Rack and fix the fixed stud bolts;

4) Repair or replace the new frame, and tighten the frame foot bolts to correct the level and strengthen the foundation;

5) Repair or replace the new frame and tighten the bearing cap Upper two bolts;

6) Repair or replace the new frame, and replace the jaws in time;

7) Repair or replace the new frame, and change the pin shaft or adjust the direction of the eccentric block to tighten the expansion sleeve.

For more information, please contact us:

Website: www.lydhcrusher.com

E-mail: lydhchina@huazn.com

Phone: +86-379-62669978

Previous Article:How to Prolong the Wear Time of Ball Mill Liner Plate

Next Article: Sand Making Machine - the Key Fine Crushing Machine