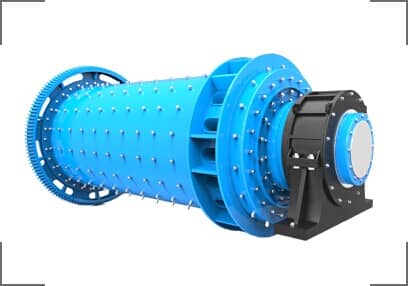

Rod Mill Steel Bar Heat Treatment Method

author:dahua1 time:2018-10-12

At present, in the production process of the rod mill wear-resistant steel rod, it is heated by the well type electric furnace and then put into the pool for quenching treatment. The material rod is only translated and cannot be rotated during the transportation and heating process. After the heat treatment by the method, the material bar is easily bent and deformed, and the hardness is not uniform; the hardness deviation of the two ends of the same bar mill wear-resistant steel bar or the positive and negative positions is also large. Because the heat-treated material has lower strength and better elasticity, it is more difficult to straighten the bar mill wear-resistant steel bar heat-treated by the well type electric furnace, and it takes several times or even ten times to achieve the effect, even if this is also the case. It is difficult to achieve a quality standard with a straightness less than or equal to l/1000 mm. At the same time, this heat treatment method has high labor intensity and high production cost, and it is difficult to bring economic benefits.

In order to overcome the above technical shortcomings, the uniformity of the heating and quenching temperature is ensured, and the bending and deformation are not performed after the heat treatment, and the production efficiency, the labor intensity, and the production cost are saved.

The production method adopted adopts the following steps:

According to different customer needs, the raw materials are cut into rods according to certain specifications and lengths; then different sizes of conveying rollers are selected according to different material rod diameter specifications. The rollers have "U" shaped grooves, which should be combined with materials. The diameter of the rod is adapted; the rod is conveyed by a roller consisting of a plurality of rolls rotating in parallel in the same direction; the rollers of the roller are inclined in the same horizontal plane, and the rod is placed on the roller. In the groove, the axis of the rod intersects the axis of the roller at an angle; when the roller rotates, the roller produces a moving component along the axial direction of the rod and a rotational component of the rotation about the axis of the rod. The rod rotates around its own axis while advancing on the roller table; the rod is conveyed to the medium frequency induction heating furnace through the roller conveyor for continuous heating, and the material rod rotates around the axis of the roller to make the heating more uniform; according to the material of the material rod, After reaching a certain temperature, the roller conveyor conveys the material rod into the quenching device, and sprays and quenches the material around the material rod; the quenched material rod passes through the roller table from the quenching device. After the surface temperature is naturally cooled and lowered to normal temperature, the material rod is sent to the box type tempering furnace through the roller conveyor to carry out the second uniform continuous heating to realize the straightening treatment; after the material rod is tempered from the box type tempering furnace, Natural cooling to obtain the grinding rod; the production technology to increase the production process and quality reliability, the production line is equipped with online infrared temperature measuring device, the conveying roller speed computer control, can automatically adjust the heating temperature and conveying roller parameters, and has a parameter memory function, again When producing products of the same material and quality, you can directly input the code number to produce according to the stable production process.

Previous Article:300t/h Construction Aggregates Production Line in Indonesia

Next Article: Luoyang Dahua 60 Anniversary Celebration