Product Knowledge

How to Make Sand from Crushing Limestone?

author:dahua2 time:2024-04-11

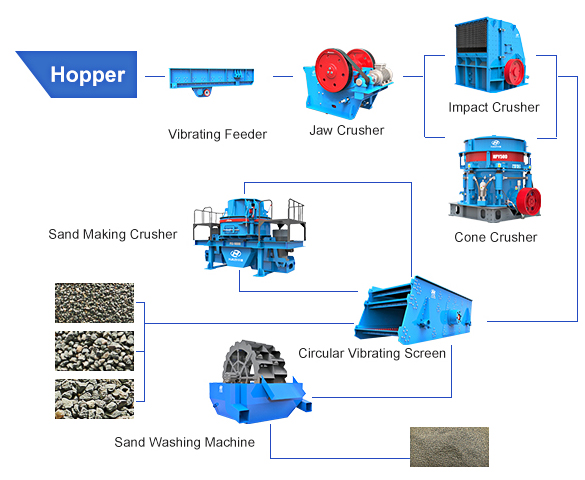

The large piece of limestone is uniform to the jaw crusher for primary crushing by the vibrating feeder;

The primary crushed material and the fine material sieved by the vibrating feeder are conveyed to the impact crusher;

The circular vibrating screen sieves the limestone after the impact crusher, and the large-grained limestone is returned to the impact crusher to re-crush, the qualified grade materials are graded and transported by the conveyor to different stockpiles.

Coarse crushing

Limestone coarse crusher: jaw crusher

The limestone jaw crusher is usually used as the first rock crusher, and it is suited for medium-size crushing of ore and bulk materials with a compressive strength of not more than 320Mpa.

Jaw crusher is divided into coarse crushing and fine crushing. The feeding size is 125mm~750mm. It often forms a complete sandstone production line together with cone crusher, impact crusher and sand making machine.

Medium crushing

Limestone medium crushing equipment recommended: impact crusher & cone crusher.

The impact crusher can granite, limestone, concrete, and the like coarse materials with a side length of less than 500 mm and a compressive strength of less than 350 MPa.

【Impact crusher VS cone crusher】

Impact crusher has a lower price, uniform discharge, less needle-like crushed product.

The cone crusher is slightly more expensive, but the wearing parts have a long life. In the long run, the cone crusher is more durable.

【Impact crusher VS hammer crusher】

The impact crusher has a larger crushing ratio and can more fully utilize the high-speed impact energy of the entire rotor.

The impact crusher is easy to wear, which makes it limited in the application of hard material crushing.

Fine crushing ( sand making )

Limestone fine crushing machine: VIS sand making machine, HX sand making machine, has a high stone crushing rate, high sanding rate, good finished grain shape.

If you need clean sand finish products, use the sand washing machine for cleaning and dewatering.

Corollary Equipment

1. Screen machine

Function: The screening machine sieves the crushed stone product into several sizes for use in different fields.

Circular vibratory screening machines are the most commonly used.

2. Ore feeder

Function: uniform and evenly feed ore material to crushers.

Automatic feeding machine, easy operation, and save labor costs.

3. Conveyor belt

Responsible for the transportation of materials. The specific configuration of conveyor belts in a limestone crushing line needs to be combined with working conditions and processing requirements.

In summary

Three-stage crushing process, high capacity

Equipment: Vibrating Feeder + Jaw Crusher + Impact Crusher + Sand Making Machine + Round Vibrating Screen + Belt Conveyor

Main Equipment: mobile jaw crusher + mobile impact crusher

Flexible, small space, lower invest, easy to construct; intelligent design, secure and convenient one-button operation.

Capacity: 50-600t/h (the maximal capacity of the mobile and semi-mobile plant are less than that of stationary)

Equipment: mobile jaw crusher + mobile impact crusher + sand making machine

Movable, less limitation; PLC control system, real-time monitoring of equipment voltage, airflow, temperature, etc., touch screen display production data, operational error voice prompts, more secure.

Huazn supply complete aggregate making machine for various sand & gravel, pebble, limestone, basalt, granite, dolomite, etc.

Includes jaw crusher, impact crusher, cone crusher, sand making machine, vibrating screen, vibrating feeder, sand washing machine, convey belt, etc.

Tag: Make Sand Crushing Limestone

Previous Article:No Information

Next Article: Which is More Suitable for Secondary Crushing , the Impact Crusher or Cone Crusher?