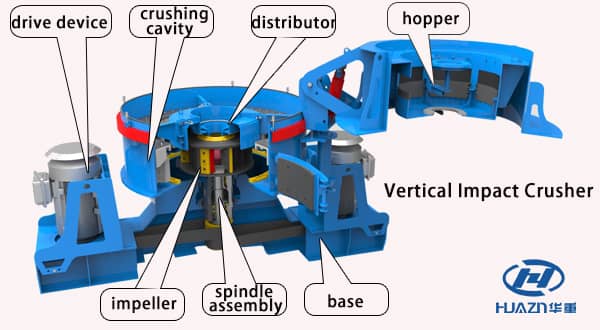

Components of Vertical Shaft Impact Crusher

author:dahua time:2019-10-09

Vertical shaft impact crusher, commonly known as sand making machine, is suitable for fine crushing of different hardness of ore and rock, its crushing performance in the ore crushing equipment plays an irreplaceable role. It is widely used in cement, refractories, building aggregates, mechanical sand, metallurgy and other industries.

Luoyang Dahua PLS vertical shaft impact crusher (sand making machine) has "stone beat stone" and "stone beat iron" two crushing modes, and the two modes can share a set of crushing cavity, through simple parts replacement, can realize these two modes exchanging to adapt different shaping demands of more materials and condition. Sand making machine includes feeding hopper, distributor, vortex crushing cavity, impeller, spindle assembly, base, and transmission device. Below, Luoyang Dahua will give the specific introduction of the components of sand making machine.

1. Feeding hopper:

The structure of the feeding hopper is an upside down prism body (or cylinder body), the feeding mouth is provided with wear resistant ring, and the incoming material from the feeding equipment enters the sand making machine through the feeding hopper.

2. Distributor:

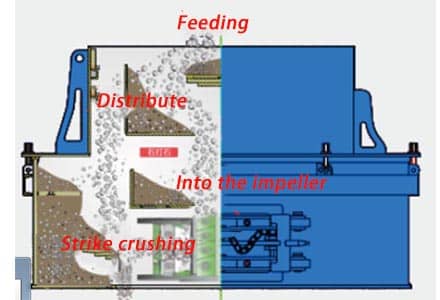

Distributor is mounted on the vortex crushing cavity. The function of the feeder is to separate the material from the feeding hopper. A part of the material directly enters the impeller through the central feeding tube and is gradually accelerated to a higher speed and ejected out, making a part of the material from the outside of the central feeding tube and bypass into the outside of the impeller in the vortex crushing cavity. No increase in power consumption, increase production capacity and improve crushing efficiency.

3. Vortex crushing cavity:

The structure of the crushing cavity is an annular space that formed by the upper and lower cylinder. The impeller in the vortex crushing cavity rotates at high-speed, and the materials can reside within the vortex crushing cavity, forming the lining material. The material crushing process occurred in vortex crushing cavity. The observation hole is to observe the wear condition of the wear-resistant block at the launching port of the impeller passage and the wear condition of the lining plate at the top of the vortex crushing cavity. The distributor is fixed on the upper cylinder section of the vortex crushing cavity.

4. Impeller:

The impeller is a hollow cylinder made of special materials, mounted on the head at the upper end of the spindle assembly. Impeller is the key element of the vertical shaft impact crusher. The material enters the center of the impeller from the center feeding tube of the upper part of the impeller. The distributor plate distributes the material evenly to each launching channel of the impeller. At the outlet of the launching channel, wear-resistant blocks made of special materials are installed, which can be replaced. The impeller accelerates the material to a speed of 60-75m/s and ejects it, impacting the material to the vortex crushing chamber for strong self-crushing. The upper and lower runner plates are installed between the cone cap and the wear-resistant block to protect the impeller from wear.

5. Spindle assembly:

The spindle assembly is mounted on the base to transmit the power of the motor through the triangular belt and to support the rotating movement of the impeller. The spindle assembly consists of bearing block, spindle and bearing.

6. The base:

Vortex crushing cavity, spindle assembly, motor and transmission device are all installed on the base. The structure of the base is in the shape of a four-prism space in the middle, and the center of the four-prism space is used to install the spindle assembly, and the discharge channel is formed on both sides.

7. Transmission device:

The drive mechanism adopts single motor or double motor driving belt (above 75KW, double motor drive). The two motors for double motor drive are installed on both sides of the spindle assembly, so that both sides of the spindle force balance, no additional torque.