Fracture and Abrasion of 5 Main Parts of Vibrating Screen

author:dahua time:2020-08-06

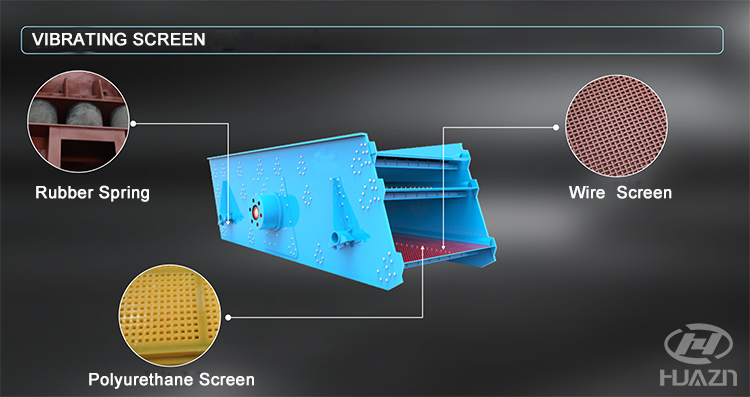

Vibrating screen is a commonly used sand making machine in the sand making production line. Some parts of the screen may be badly worn or even broken after long use. The commonly worn parts include springs, bearings, beams, pipe beams and screen racks, etc. The following solutions are provided when the 5 parts are worn:

1. Screen racks fracture

Screen rack breaks are usually caused by the shaking of the vibrating screen during operation. In this case, the side plate can be thickened, or the side plate near the vibrating screen can be added to increase the bearing capacity of the screen rack.

2. Bearings wear or fracture

Bearing is an important component of vibrating screen. There are many causes of bearing wear and fracture. Once the bearing is worn or damaged, the vibrating screen must be stopped and the bearing replaced.

3. Pipe beams fracture

When the vibrating screen dehydrates, if the washing force of the water flow is too strong, water may leak from the gap between the sieves during the washing process, thus affecting the tube bundle. If the wall of the tube bundle is too thin, it is easy to wear out or break. If the tube bundles are not seriously worn, they can be repaired along the longitudinal direction of the bundles.

Therefore, when selecting the vibrating screen, try to select the same type of thick wall pipe beam or a larger size. This increases the thickness of the wall of the bundle. It can also add horizontal or vertical curling to reduce leakage.

4. Springs wear or fracture

The vibrating screen spring is an important part to reduce vibration and noise. If the spring is seriously worn or broken, the vibrating screen may produce noise during operation, which may affect the normal operation of the vibrating screen. In this case, it is necessary to replace the spring in time to prevent accidents.

5. Beam fracture

The beam fracture of vibrating screen is usually caused by long working time, loose bolts, deformation of springs, difference of left and right height, and large beam error caused by eccentric block. In this case, you need to stop the work in time, replace the structural parts, and tighten the loose bolts to adjust the mass of the eccentric block.

Vibrating screen is the necessary machinery in sand making production, the faults should be solved in time. Luoyang Dahua is focus on manufacturing crusher machine, mill machine, vibrating feeder and screen for more than 30 years, the company has rich experience in machine design, manufacturing, and troubleshooting. If you encounter any problems during production, please contact us, our sales manager will reply you within 12 hours. Website: www.lydhcrusher.com Email: lydhchina@huazn.com