How to Choose the Cavity Type of Multi-Cylinder Hydraulic Cone Crusher?

author:dahua1 time:2019-10-25

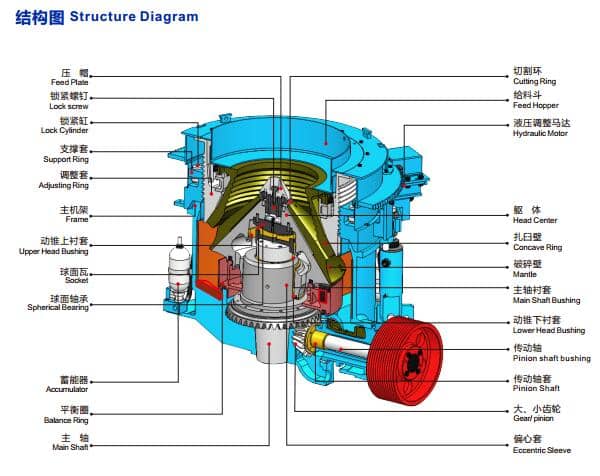

HPY series multi-cylinder hydraulic cone crusher is a new type of multi-cylinder hydraulic cone crusher designed and developed by luoyang dahua heavy industry after optimization and upgrading on the basis of referring to European and American cone crusher technology and combining with the actual situation in China. This machine is widely used in metallurgy, mining, sand and stone aggregate, cement mine and other industries of a variety of minerals and rocks, medium and fine crushing operations, can be broken river pebbles, granite, basalt, limestone, dolomite construction concrete stone and non-ferrous metal ore and other materials. From this, it can be seen that the multi-cylinder hydraulic cone crusher has a wide range of applicability, but the crushing of different materials or in the multi-cylinder hydraulic cone crusher cavity choice carefully choice, cavity choice will affect the size of the product and output.

The multi-cylinder hydraulic cone crusher determines the type of crushing cavity according to the use of ore. It can be divided into two types: standard type and short type. The applicable range, basic structure and working principle of the two cones are basically the same, but only in the crushing chamber. The shape is different. The difference between the standard and short-head cone crushers is that the shape of the crushing chamber is different. The key is that the crushing parallel has a big difference. The standard cone crusher has a shorter parallel belt, and the feed port and the discharge port are relatively larger, so the crushed product has a coarser grain size and a higher output. The standard type is suitable for the medium crushing of the material; the short head type cone crusher. The broken parallel belt is long, and the crushed product has fine grain size, and is often used for fine crushing and superfine crushing of materials.

1. The nature of the broken material and the output size: In general, the price of a cone crusher is not cheap, and it is necessary to consider the cone crusher. For example, if you want to crush a material with a small hardness such as limestone, you can use a hammer crusher. In addition, the appropriate cone crusher model is selected based on the output, finished product, and the like.

2. The size of the feed material and the size of the discharge size: the size of the feed material is large, and the particle size of the product will be small. In this case, the extra coarse or coarse cone is used, and the medium or fine is used instead. At the same time, we must also consider the large feed size, particle size change; feed particle size distribution, material hardness, and material wear resistance and so on.

3. Liner of the cone crusher: the longer the lining, the higher the power consumption. Select short liner for hard materials and long liner for soft materials. In the distribution of materials, the short material is selected as the short material, and the long material is selected as the long material. In the distribution of the feed size, in general, the material of the discharge port at the closed side cannot exceed 10%. If it exceeds, the power consumption it will raise and the product will appear in a sheet.

Therefore, when you buy a multi-cylinder hydraulic cone crusher, the choice of the crusher cavity type is particularly important. You should choose according to the material properties of your own broken materials, and consult the factory technicians. Welcome everyone to come to Luoyang Dahua Heavy Industry to inspect the plant and crusher, consult the crusher selection and production line design issues, we will have professionals according to the material properties you want to break, the characteristics of the production area to equip you with the right crusher, design The right production line!

Previous Article:Wet Dust Removal VS Dry Dust Removal

Next Article: Operation Regulation of Vibrating Feeder