How to choose Impact Crusher and Hammer Crusher? What's the Difference between Them? (Part 1)

author:dahua time:2020-04-24

As widely used crusher machinery, impact crusher and hammer crusher are often compared. They are simple to operate, have favorable price. They have certain similarities from the principle of crushing to the structure of the equipment. Can they be used universally? What's the difference? The following is a detailed distinction.

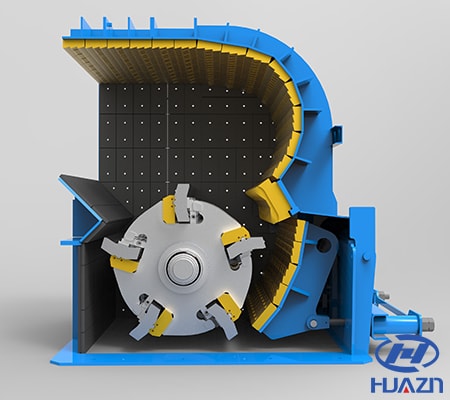

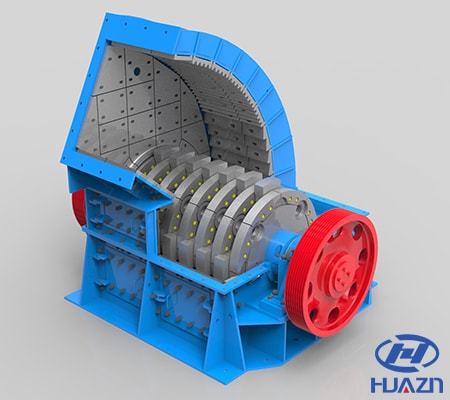

1. Structure composition

Impact crusher is composed of rotor, hammer plate, striking plate, frame, impacting plate, and transmission components, etc. The striking plate is connected with rotor.

Hammer crusher is composed of rotor, hammer head, hammer frame, pin shaft, frame, crushing plate, screen plate, transmission components, and hammer head hinge in the hammer frame.

2. Crushing cavity

The crushing chamber of impact crusher is larger, so that the material has a certain space for movement and makes full use of the impact effect.

Hammer crusher's crushing cavity is small, the impact cannot play a full role, and impact cavity is multi-cavity broken structure, crushing more fully.

3. Crushing principle

The hammer plate and the rotor of impact crusher are rigidly connected, and the whole rotor's inertia is used to impact the material (free crushing, impacting crushing, milling crushing), so that it is not only crushed but also to obtain greater speed and kinetic energy. The hammer is to meet the input material from the bottom up for impact crushing, and throw it on the upper counter plate.

The hammer head of hammer crusher is a single impact on the material crushing (free crushing, impacting crushing), the speed and kinetic energy of the material is limited. Hammer head is down the direction of the material to hit the material, has small crushing effect.

4. Wear resistance of wearing parts

The wear of impact hammer often appears on the side facing the material, and its metal utilization rate can be as high as 45%-48%. When crush limestone, the impact hammer is not seriously worn, but in the case of crushing granite (high hardness, can use cone crusher), it is necessary to constantly replace the hammer.

The hammer head of hammer crusher is in a hanging state, and the wear occurs on the top, front, back and side. Compared with the plate hammer, the hammer head is more severely worn. The metal utilization rate of the hammer head is about 35%, and the rotor body itself may be worn.

In addition, if the sieve plates at the bottom of hammer crusher are seriously worn, the barrier should be completely replaced, and the work of replacing the sieve plates is also more complex.

Previous Article:How to choose Impact Crusher and Hammer Crusher? What's the Difference between Them? (Part 2)

Next Article: Mobile Stone Crusher Advantages