Product Knowledge

Huazn Complete Limestone Crushing Plant Machines

author:dahua2 time:2024-05-23

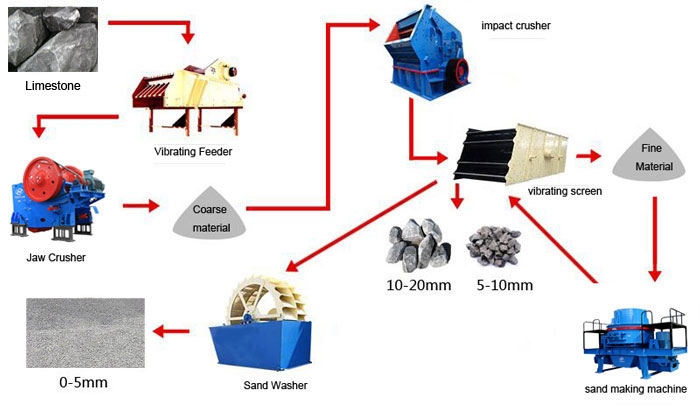

The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment. To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etc. The jaw crusher performs coarse crushing of sand and gravel, and the feeding force is large. The impact crusher finely crushes the sand and gravel, with a small size and low energy consumption. The cone crusher performs fine crushing of high hardness, strong crushing force, and high safety factor. Sand-making machine processing capacity Strong, uniform grain shape.

Feeding stage

Vibrating feeders, which can feed materials into the crusher evenly, quantitatively, and continuously, are commonly used.

Crushing stage

The process involves several crushers, mainly coarse crushing, and medium and fine crushing equipment. Jaw crushers are mainly used for coarse crushing, and cone crushers and impact crushers are mainly used for medium and fine crushing equipment. They can process hard rocks, such as granite, and soft rocks, such as limestone.

Sand-making stage

The sand-making stage is generally used after the crushing stage. A vertical shaft impact crusher is commonly used, which can further finely crush and shape the stones produced by the crushing process to produce machine-made sand specifications of less than 5mm.

Screening stage

The screening operation is an auxiliary process. The finished sand and gravel materials from crushing or sand-making processing are screened through the vibrating screen to obtain the finished product specifications and gradation.

Conveying stage

Conveying and screening are also auxiliary processes. A belt conveyor is an ideal and efficient continuous conveying equipment with continuous conveying, reliability, convenience, long conveying distance, low energy consumption, large conveying capacity, and green and environmental protection.

Sand washing and dust removal stage

Dust removal equipment and sand washing equipment are generally configured as needed. Under the requirements of environmental protection, dust pollution is minimized. The sand washing machine is generally equipped with a wheel sand washing machine with high output, simple operation, and convenient operation.

Our company can design complete solutions and contract overall projects for limestone sand and aggregate plant with below 2000 TPH. Besides this kind of fixed crushing line, we also have mobile liemstone sand and aggregate making plant for sale.

Previous Article:No Information

Next Article: Types of Crushers for Mineral Processing