Product Knowledge

Key Points for Selecting Bluestone Crushing Equipment

author:dahua2 time:2025-12-04

Bluestone (Mohs hardness 3-4) is a medium-hardness material. Bluestone crushing equipment combination should be selected based on output, output particle size, and process requirements. A reasonable combination of coarse crushing, medium and fine crushing, and sand making equipment is necessary. Due to the high hardness of bluestone, it is recommended to use a wear-resistant jaw crusher for coarse crushing, a cone crusher for medium and fine crushing, and finally a vertical shaft impact crusher for shaping to ensure good finished product particle shape.

1. Jaw Crusher (Coarse Crushing)

Applicable Scenarios: Processing large pieces of bluestone (feed size ≤1200mm), compressive strength ≤320MPa.

Selection Parameters:

Feed opening width: 430-1300mm (JC series jaw crusher).

Motor power: 75-400kW, hourly output 50-2000 tons.

Advantages: Simple structure, low maintenance cost, suitable for primary crushing.

2. Cone Crusher (Medium and Fine Crushing)

Applicable Scenarios: Medium and fine crushing with high particle shape requirements (discharge particle size 5-20mm).

Selection Parameters:

Feed Size: 65-370mm (GPY series single-cylinder cone crusher).

Power: 90-750kW, output 45-2188 tons per hour.

Advantages: Layered crushing principle, uniform finished product particle shape, long service life of wear parts.

3. Vertical Shaft Impact Crusher (Fine Crushing/Shaping)

Applicable Scenarios: Sand making or shaping (discharge particle size 1-5mm), when high particle shape quality is required.

Selection Parameters:

Feed Size: ≤60mm (PLS series crusher).

Power: 30-500kW, output 24-1100 tons per hour.

Advantages: Utilizes stone-on-stone/stone-on-iron principle, resulting in well-graded finished sand with low needle-like and flaky content.

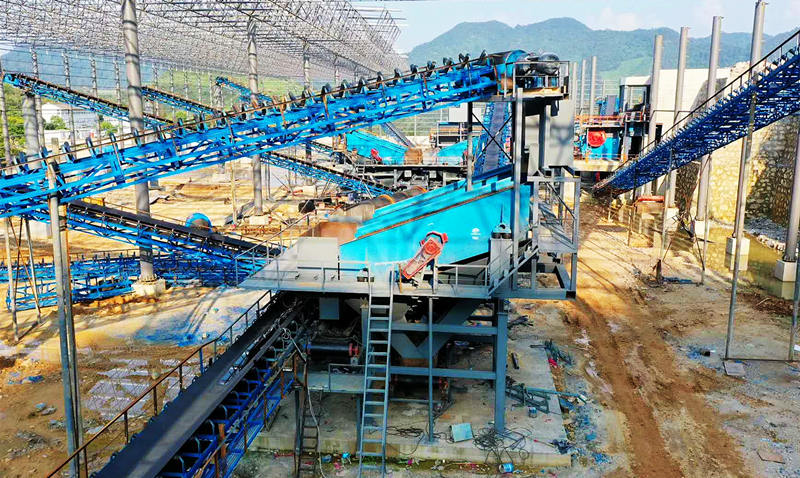

Bluestone Crushing Production Line Configuration Recommendations:

Low Output (<100 tons/hour): Jaw crusher + impact crusher/hammer crusher.

Medium-to-high Output (≥100 tons/hour): Jaw crusher + cone crusher + sand making machine.

Layout Optimization: Designed with reference to equipment spacing and material flow direction to reduce energy consumption.

Luoyang Dahua Heavy Industry Science and Technology Co., Ltd. is a direct-sales manufacturer integrating R&D, production, sales, and service. We provide various types of mining crushing equipment, offering high quality and reliability. We optimize combinations of various equipment models, tailor-make supporting equipment and construction plans to meet different process requirements. We serve you from equipment selection, site inspection, equipment manufacturing, installation, commissioning, and delivery. Welcome to visit Luoyang Dahua Heavy Machinery for on-site inspection and we will provide you with professional support!

Previous Article:No Information

Next Article: Modular Crushing Plants Boost Production Efficiency and Reduce Operating Costs