The Installation Points of 5 Major Components of Gyratory Crusher

author:dahua time:2021-03-03

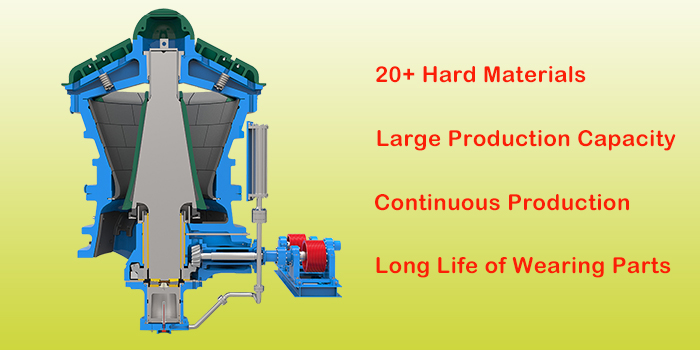

Gyratory crusher can be used in the large scale stone crushing production line for coarse crushing. Today, let's talk about the installation points of 5 major components of gyratory crusher.

1. Installation of the lower frame

The installation of the lower frame is the basis of equipment installation. The lower frame is installed on the foundation first, and the equipment and the foundation should be consistent when installing. The gap between the base of the lower frame and the foundation should be kept no less than 30mm due to the secondary grouting. Tighten the anchor bolts after the second grouting to ensure the stability of the crusher equipment.

2. Installation of the transmission part

The installation of the transmission part is related to the operation of the gyratory crusher, so when installing, we must pay attention to the center of the two copper sleeve to always maintain at the same level, without deviation, and the radial clearance between the copper sleeve and the shaft should also be strictly in accordance with the instructions of the equipment manual, and keep within a certain range. When installing the drive shaft, it is necessary to add proper amount of gasket between the flange and the frame of the transmission housing to adjust the position of the bevel gear, so that it meets the design requirements of the gyratory crusher.

3. Installation of eccentric shaft sleeve

Special care shall be taken during installation to protect the smooth and integrity of the friction surface of the Babbitt layer. Check whether the clearance of tooth top meets the requirements after installation. If any abnormality is found, correct it in time. The size of the clearance can be adjusted by changing the number of adjusting gaskets.

4. Installation of the middle frame

The installation of the middle frame needs to be calibrated by the upper flange of the lower frame. Before installation, the clearance between all the flanges that contact the cone surface should be equal, and the error should be less than 0.5mm. The clearance between the upper and lower joint surfaces is generally about 15mm. When installing, make sure that the pins are tight. After the machine runs for a period of time with load, the pins are pressed one by one again to make all the pins on the circumference of the circle bear uniform force, strengthen its stability and ensure the normal operation of the gyratory crusher.

5. Installation of crushing cone and beam

(1) Separate installation of crushing cone

The crushing cone is hoisting into the frame with the lifting ring on the shaft, and then wooden pads are placed on the bars at the lower part of the frame to support the cone, then the beam is installed, and the nut and coat at the upper end of the main shaft are installed, and finally the cap is installed, and then the wooden pads and wooden wedges are removed.

(2) The crushing cone shall be installed together with the beam

It is to install the beam and the crushing cone on the special pit in advance, and then install them together into the frame. When lifting the crushing cone and beam assembly of the gyratory crusher, attention should be paid to the lifting method. The steel wire rope must be used to hang on the beam to prevent accidents in the lifting process. The crushing wall of the crushing cone must be pressed tightly to prevent loosening. Before pressing, the lower space of the fixing ring (pressing plate) and the anastomosis bolt should be covered with dry oil to prevent rust or corrosion.

Luoyang Dahua, as a supplier of crusher machinery and grinder equipment, is committed to providing customers with crushing equipment with superior performance, good quality and stable operation. Production workshop covers an area of about 200,000 square meters, with advanced processing equipment, storage workshop clean and tidy, 5S standardized production management. If you want to know more about us, please contact: lydhchina@huazn.com.

Previous Article:What are the Factors Affecting the Price of Jaw Crusher?

Next Article: How much is the full set of sand making production line equipment?