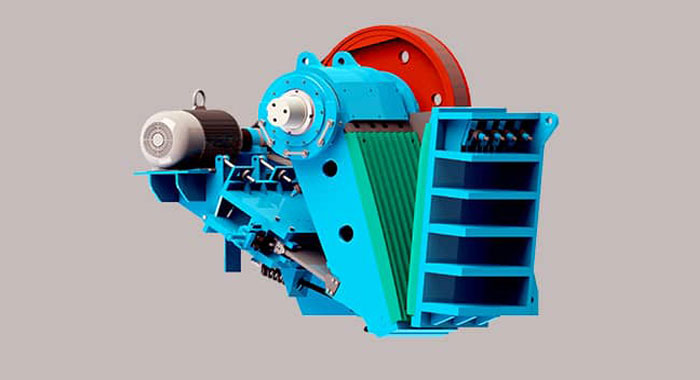

The Wear Parts of Jaw Crusher

author:dahua2 time:2022-08-09

As a commonly used rough crushing equipment, the jaw crusher is the pioneer equipment of the crushing production line. The long-term high-intensity operation of the jaw crusher is very serious, and many parts are easy to wear during the working process, so it is necessary to frequently Replacement, then what are the wearing parts of the jaw crusher, and how can the service life of the wearing parts be extended?

For the jaw crusher, its wearing parts mainly include movable jaw plate, fixed jaw plate, lining plate, toggle plate, eccentric shaft and bearing. In the actual production process, the abnormal wear of wearing parts is not only related to the structural defects of the equipment, but also related to the excessive hardness of the material, the coarse particle size of the material, the unsatisfactory lubrication effect of the equipment, and environmental factors.

1. Jaw plate

The service life of the jaw plate mainly depends on the production time and the degree of damage. The service life and wear degree of different crushed materials are also different. Generally, it needs to be replaced once a year. If it is used to crush soft and medium-hard materials, it can be used for two years.

2. Axis

If the wear of the shaft is small, just to repair its geometry, it can be turned on a lathe to make the journal reach the correct geometry, and then reduce the bearing inner diameter accordingly. However, after several such treatments, if the size of the journal is reduced by 5% compared with the original, turning is not allowed, and a new shaft should be replaced.

3. Liner

The fixed jaw lining plate, movable jaw lining plate and the lining plates on both sides of the jaw crusher are easy to wear and tear. If the wear is fast, it will affect the size of the product. When turning around, the wear of the jaw plate is mostly concentrated in the middle bottom. When the tooth plate is worn out by 3/5, the lining plate needs to be replaced, and when the lining plates on both sides are worn out by 2/5, it also needs to be replaced.

4. Toggle plate

When the toggle plate is worn out or broken, the stones in the crushing chamber must be removed first, the quickly worn or broken toggle plate shall be taken out, and the toggle plate on the movable jaw and the connecting rod shall be checked for damage, and then the movable jaw shall be pulled to the fixed position. When the jaw is near, lubricate the working surface of the toggle plate with dry oil, then replace it with a new thrust plate to make it gradually contact with the working surface of the toggle plate, and tighten the pull rod, so that the movable jaw clamps the thrust plate, and tightening is safe cover, connect the lubrication system, and then adjust the size of the outlet.

5. Eccentric shaft, bearing box

If the eccentric shaft and bearing box are worn and the space exceeds 1.5 times of the original installation space, it needs to be adjusted or replaced with a pad; the oil groove should be re-opened and adjusted if the oil groove is worn by 1.5mm; the upper cover of the connecting rod head and the eccentric shaft When the space between them is worn to more than 1.5 times of the installation space, they must be adjusted or replaced with pads.

To prolong the service life of wearing parts of jaw crusher, first of all, manufacturers should choose materials with excellent wear resistance to enhance the service life of wearing parts and reduce the cost of users. Secondly, users should standardize the premise of using crushing equipment and do a good job Repair and maintenance of parts, strengthen the inspection process, and replace them in time when they are found to be worn out, so as to prevent greater damage to the equipment and even delay the normal operation of the entire crushed stone production line.

Previous Article:No Information

Next Article: How to Improve the Screening Efficiency of Circular Vibrating Screen?