Factors affecting the Screening Efficiency of Vibrating Screen ( I )

author:dahua time:2020-11-03

Vibrating screen screening is a crucial link in the production of mines, chemical plants, and cement plants, etc. Screening efficiency refers to the ratio of the actual quality of the screened product to the material containing less than the sieve hole in the feeding material. Screening efficiency directly affects the production benefit. This paper shares the factors affecting the screening efficiency of vibrating screen.

1. Nature of materials

(1) The more easily sieving particles are contained in the particle size composition, the easier the material is to be sifted, and vice versa. The materials with particle size d=1 ~ 1.5a (a is the size of sieve hole) are easy to get stuck in the sieve hole of vibrating sieve, which are called blocking particles and affecting the material to pass through the sieve hole. Therefore, the more difficult and obstructed materials are, the lower the screening efficiency of vibrating screen will be.

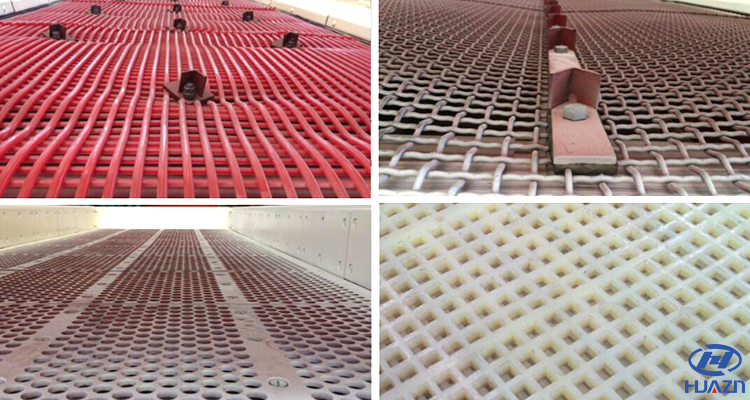

(2) Particles with spherical shape are easy to pass through the square hole and circular hole, while strip, sheet and polygonal materials are more difficult to pass through the square hole and circular hole vibrating screen, but easier to pass through the rectangular hole vibrating screen.

(3) Water content. During dry screening, the material with high moisture and better wetting and adhesion is more likely to agglomerate and clog the screen hole, which greatly reduces the screening efficiency.

(4) Accumulation density. In the case of high material bulk density, the screening capacity of vibrating screen is proportional to the bulk density.