How to Choose the Right Vibrating Screen?

author:dahua2 time:2022-04-28

Screening work is an indispensable link in the sand and gravel aggregate production line. As an important screening equipment, the working efficiency of the vibrating screen directly affects the economic benefits of the sand production line. But there are many kinds of vibrating screens, and many people do not know how to choose. How to choose the right vibrating screen?

1. Pay attention to the nature of the screening material

When selecting a vibrating screen, screening material should be considered of the shape, moisture content, clay content, etc. Appropriate materials can improve the production efficiency of the vibrating screen. For example, when the sand making production requires high gradation, it is suitable to use a square screen with square holes, but not a rectangular or circular screen.

2. Pay attention to the structure of the vibrating screen

When selecting a vibrating screen, factors such as the screen area, movement mode, and vibration frequency of the vibrating screen should also be considered. For example, when the moving sieve is screening particles, the particles can shake on the screen surface in the direction close to the vertical screen hole, and the vibration frequency is high, and the screening effect is better.

3. Pay attention to the production volume of the vibrating screen

The production volume of the equipment should be in line with the production volume stipulated by the company. If the production volume is too rich, capital investment will be wasted. Overload operation will cause wear and tear of the equipment and reduce the production capacity. Appropriate production volume can reduce unnecessary waste of funds.

4. Pay attention to the screening purpose of the vibrating screen

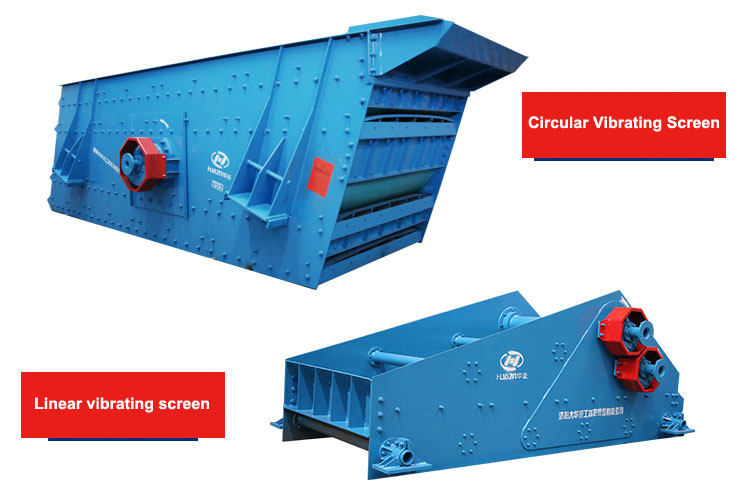

According to different screening purposes, different types of vibrating screens need to be selected. For example, a circular vibrating screen can be used for pre-screening materials; a large-scale vibrating screen can be used for grading and screening of crushed materials; Linear vibrating screen; Probability screen can be used for desilting and sand cleaning of materials.

5. Pay attention to the applicability of vibrating screen

Applicability means that the vibrating screen selected by people can adapt to the production environment. The structure and manufacturing materials of the vibrating screen should be able to adapt to the production environment. The higher the applicability, the higher the production efficiency.

6. Pay attention to the requirements of the beneficiation process

When choosing vibrating screen, we should also pay attention to the requirements of the beneficiation process. According to the processing capacity of the production line, the screening method, etc., the appropriate screen surface, screen hole shape and screen size are selected, which can improve the screening effect of sand and gravel materials. The research shows that the larger the screen size, the larger the fineness modulus of the produced machine-made sand, and the lower the stone powder content; the smaller the screen size, the smaller the produced machine-made sand's fineness modulus, and the larger the stone powder content.

The above are the 6 tips for choosing a vibrating screen. When buying a vibrating screen, you should choose according to your own project needs, pay attention to the properties of the screening material, the structure of the vibrating screen, the production volume of the vibrating screen, etc., and consult more vibrating screen knowledge , please contact the online customer service staff of Dahua Heavy Industry, we will serve you wholeheartedly!

Previous Article:No Information

Next Article: The Process of 400t/h Wet Process High Efficiency River Pebble Sand Production Line