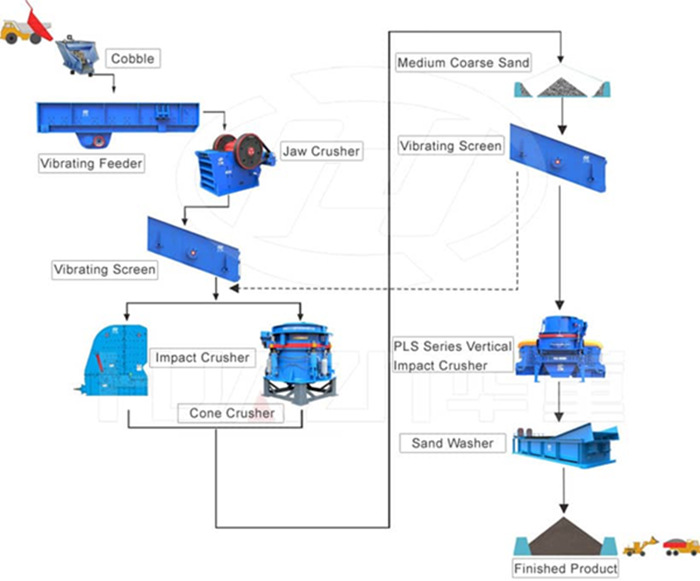

River Pebble Tertiary Crushing Production Line

author:dahua2 time:2022-02-15

The main chemical component of river pebble is silicon dioxide, which has a hard texture and high compressive strength. The Mohs hardness reaches between 7 and 8. During the crushing process, the wear of wear-resistant parts is very serious. For the crushing of this kind of high hardness and high wear resistance material, we need to use at least tertiary or more crushing processes.

Generally, we will perform a screening process before crushing the river pebbles. After all, some river pebbles are relatively small in diameter and can be directly entered into the second crusher for crushing. It is even said that a part of natural sand can be directly screened out.

Coarse crushing stage of crushing river pebble : For the coarse crushing of river pebble, we use jaw crusher, which has a simple structure and stable operation. The crushing capacity is large, the specifications of the feeding port are various, and the diameter of the material that can be crushed is also large. The jaw crusher is suitable for coarse crushing of various materials. Even if some of the pebbles crushed by the jaw crusher are not directly broken, they have already been squeezed, and they will be easier to break than the original stone in the next stage.

The middle crushing stage of crushing river pebble : for the secondary crushing of river pebbles, we generally use cone crushers. The particle size of the material mouth can be adjusted in a wide range, and it can basically produce qualified products with uniform particle shape (if the requirements of the finished particle shape are not so strict, the stone material that is broken through the cone can be used as the finished material).

The fine crushing stage of crushing river pebble: through the first two stages of coarse crushing and medium crushing, the original large-diameter river pebbles have been basically crushed to a size close to the size of the finished building aggregates, but if there are requirements for the finished grain shape, In other words, for sand making from river pebble, we also need to carry out the crushing operation of fine crushing. The part of fine crushing can be called shaping crushing or sand making crushing. In this crushing stage, it is most suitable to use an impact crusher or a vertical shaft impact crusher. The choice of these two equipment depends on the needs of the proportion of sand and gravel. If the required proportion of stones is large, then we can use impact crusher for fine crushing operation, if the required proportion of sand is large, then we use vertical shaft impact crusher for final fine crushing operation.

Screening and grading stage: After the river pebbles are crushed by the crusher, they need to be screened again. The stones or sand that meet the particle size requirements are transported to the finished material area by the conveyor belt, and the stones that do not meet the specifications are returned to the crusher to be crushed again.

Previous Article:No Information

Next Article: How to Improve the Working Efficiency of Sand Washing Machine