Use and Maintenance of Impact Crusher

author:dahua time:2019-09-12

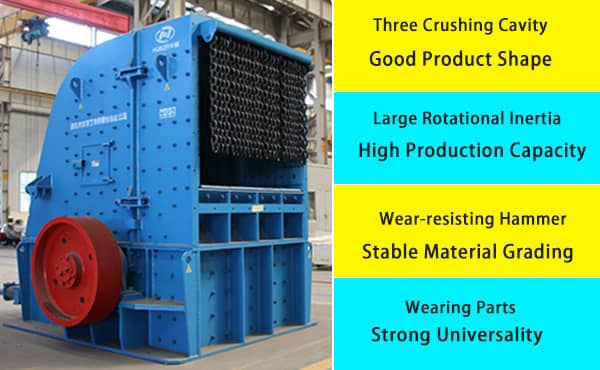

Impact crusher is widely used in the fine crushing process, the good use and maintenance can enhance the crusher working efficiency, and prolong the service life.

1. Use of impact crusher

It is strictly forbidden to modify the crusher structure without informing the manufacturer.

Feed the materials strictly according to the operation manual, consecutive and uniform.

Check the discharging situation regularly, check the wear condition of hammer and liner plate after stopping the machine, and check the gap between the hammer and liner plate through observing door, so as to adjust the gap subsequently.

Iron removal device must be added before feeding.

2. Maintenance of impact crusher

Add lubrication oil into the bearing regularly, change the oil every six month.

When install or replace the new part, the fasteners should be tightened regularly and checked once per shift to prevent the liner bolts from loosening.

When the bearing temperature rising or appear abnormal sound, should replace the new one.

Take record at each shift, such as the abrasion situation of wearing parts, bearing temperature rise, products granularity, and machine operation situation, etc.

3. Lubrication

Impact crusher adopts the universal lithium grease lubrication, and generally adds 20~50ml once a week.

Previous Article:Dry Sand Making VS Wet Sand Making

Next Article: Advantages of GPY Series Steel Slag Special Hydraulic Cone Crusher in Steel Slag Treatment