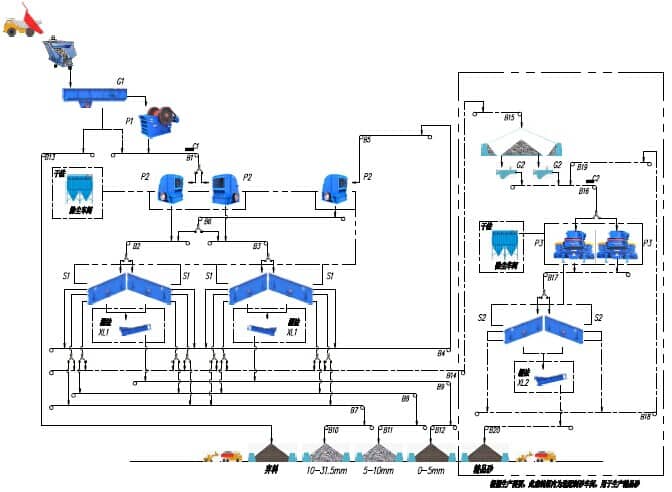

1000T/H Granite/Basalt Aggregate Production Line

|

No. |

Equipment |

Model |

Unit |

Qty |

|

G1 |

Bar feeder |

ZSW600×210 |

station |

1 |

|

P1 |

Jaw crusher |

JC160 |

station |

1 |

|

G2 |

Vibrating feeder |

ZG400 |

station |

3 |

|

G3 |

Vibrating feeder |

ZG500 |

station |

3 |

|

P2 |

Cone crusher |

GPY500S |

station |

1 |

|

P3 |

Cone crusher |

HPY500 |

station |

3 |

|

S1 |

Vibrating screen |

3YK2460 |

station |

4 |

|

XL1 |

Sand washing machine |

XL914 |

station |

2 |

|

C1 |

Iron removal machine |

|

station |

1 |

|

G3 |

Vibrating feeder |

ZG200 |

station |

2 |

|

P4 |

Sand making machine |

PLS-1200 |

station |

2 |

|

S2 |

Vibrating screen |

2YK3073 |

station |

2 |

|

XL2 |

Sand washing machine |

2XL914 |

station |

2 |

|

C2 |

Iron removal machine |

|

station |

1 |